Food Safety Department

Food Safety Department

The Belize Agricultural Health Authority is the competent authority for Food Safety in Belize. In this capacity, the Food Safety Services, one of the four technical departments of BAHA oversees, along with relevant partners and stakeholders, the National Food Control System of Belize thereby ensuring, as best as possible, that the food available for consumption and produced within the country is safe and wholesome. The Food Safety Services has responsibility and authority for monitoring, inspecting, approving and controlling food safety systems of food processing establishments, and for regulation of export and import certification for food commodities. These responsibilities are supported in law by the BAHA Act, Ch. 211 of the Substantive regulations of Belize, and other enabling regulations including the Belize Agricultural Health Authority (Food Safety) regulations, S.I. No. 25 of 2001.

Food Safety Priorities

The Food Safety Department conducts Food Safety inspections that evaluate hygienic practices of food processors.

Import permits regulate the importation of food products into Belize

Food safety export certificates are issued for food products from registered establishments approved for exportation.

Food safety registration is mandatory for exporting food enterprises registered with BAHA’s Food Safety Services.

BAHA Food Safety inspectors oversee meat inspection at registered slaughterhouses in the country. The inspection program has two main goals: ensuring that only healthy animals are slaughtered for human consumption and that these animals are free from zoonotic and other diseases.

Food safety inspections ensure that food producers adhere to Good Manufacturing Practices (GMP), which are mandated operational standards for producing safe food. These practices are outlined in the BAHA (Food Safety) Regulations. Inspections verify compliance with these standards, safeguarding the production of safe food for consumers.

Food safety microbiological testing is conducted at the Central Investigation Laboratory in Belize City, analyzing foods, feed, and water for foodborne pathogens and indicator bacteria. Tests available include screening for pathogens such as Salmonella spp., Staphylococcus aureus, Vibrio cholerae, as well as Aerobic Mesophilic bacteria, coliform bacteria, and Escherichia coli (E. coli). These tests help ensure the safety of food products by identifying harmful microorganisms that could pose health risks to consumers.

Food Safety services oversee sanitary audits of HACCP programs on Belize-flagged High Seas Fishing Vessels (BHSFU), registered by IMMARBE and licensed by BHSFU. These audits, crucial for international market access like the EU, ensure the safety of fishery products. Authorized vessels can export to the EU under specific regulations, with BAHA recognized as the Competent Authority. This ensures health controls and final conditions for fishery products exported from Belize, maintaining compliance with EU standards.

The Chemical Analysis Laboratory at the Food Safety headquarters in Belize City conducts comprehensive testing for chemical residues and contaminants in foods, feeds, and agricultural samples.

HACCP (Hazard Analysis and Critical Control Point) is a food safety system aimed at preventing hazards in food production. BAHA audits registered food processing enterprises annually to ensure HACCP compliance.

Ensuring Food Safety Through Inspections of Food Establishments

BAHA’s Food Safety Services inspectorate conducts routine inspections of registered food processing establishments including slaughterhouses, fish & fishery processing facilities, dairy and agro-processing facilities. Inspections verify compliance of the food producer with Good Manufacturing Practices (GMP) which are the legislated operational requirements necessary to enable a food business to produce safe food (Second Schedule “General Principles of Food Hygiene” of the BAHA (Food Safety) Regulations (S.I. No. 25 of 2001).

What Is Food Safety Inspections?

Food safety inspections are systematic assessments conducted by the Food Safety Services of the Belize Agricultural Health Authority to ensure that food processing establishments comply with established food safety standards. BAHA’s food safety inspectors evaluate various aspects of food production, including hygiene and sanitation practices, processing methods, facility layout, process flow, and storage conditions

Importance of Food Safety Inspections

- Protecting Public Health: All animals destined for slaughter are screened for abnormalities which can indicate poor health, sickness or clinical disease, and foods that are unfit for human consumption are condemned and destroyed.

- Ensuring Product Safety: Food Safety inspections verify compliance of the food producer with Good Hygiene Practices and Good Manufacturing Practices (GMP) which minimize the risk of food contamination

- Building Consumer Confidence: Regular inspections of registered facilities ensure that consumers can trust the safety and integrity of the food supply chain.

Key Areas of Food Safety Inspections

Ensuring that processing conditions and procedures follow Good Hygiene Practices and Good Manufacturing Practices (GMP) to prevent contamination and maintain food quality. Some key aspects of GHP and GMP include:

- Building and equipment design: Layout and design should prevent contamination of product. This includes the structure of and materials of which walls, ceilings, food contact surfaces are constructed, location and design of sanitary facilities, entrances and exits and flow of production process …………………

- Storage Facilities: there must be adequate segregation, chill storage for materials that require refrigeration, and distribution……….

- Process Equipment/Machinery: must be of proper …. To allow proper cleaning and disinfection and must be non-toxic. Constructed and maintained to preclude contamination

- Personnel Standards: attire must be clean, PPE headgear to cover hair, handwashing practices; jewelry, cosmetics

- Food Handling Practices:

- Quality Assurance: Product and Production processes, Processing ?Conditions? including environmental conditions should be monitored and controlled including temperatures, cleaning?

- Pest Prevention: Iwritten t is critical to avoid contamination of ingredients/incoming materials, products and food contact materials/surfaces by pests. Pathogens /sources of Human disease

- Cleaning System: water, chemicals, written

- Management Control: policies and resources

Food Establishment Registration: Ensuring Safe and Quality Food for Everyone

Food establishment registration involves the official recording of a food establishment with BAHA’s Food Safety Services. Food Export Enterprises are legally required to register with BAHA. Registration ensures that these establishments meet specific safety and hygiene standards. Registered establishments fall under the Food Safety Services’ inspection and monitoring program; they are routinely inspected for compliance with Good Manufacturing Practices and other national Food Safety requirements, and their products are regularly sampled and tested.

For first time registration of a food establishment a completed registration form with information on the food establishment including legal name, legal status, location, size, scope of production, production volumes, description of the production process, facility layout and design and other information of relevance is submitted. A preliminary evaluation is conducted based on the documents provided to ensure the establishment design and process flow are appropriate. This documentary evaluation is followed by a physical inspection of the establishment for compliance with GMPs. GMPs or Good Manufacturing practices are the operational requirements necessary to enable a food business to produce safe food. A food establishment is approved or not approved for registration based on results of the inspection.

Registered establishments are issued a certificate of registration with one year validity period. These establishments are routinely inspected, and the products and process water monitored to determine that they meet microbiological and chemical quality/safety criteria. The food establishment registration is subject to renewal on an annual basis based on the establishment’s performance in food safety inspection and monitoring programs. Registered establishments must comply with all legal food safety requirements. Failure to comply with national food safety regulations can results in withdrawal of an establishment’s registration; ongoing contravention of regulations is grounds for suspension/revocation of the establishment’s registration certificate.

What is the Process of Registering your Food Establishment?

For first time registration of a food establishment, a completed registration form with information on the food establishment including legal name, legal status, location, size, scope of production, production volumes, description of the production process, facility layout and design and other information of relevance is submitted. A preliminary evaluation is conducted based on the documents provided to ensure the establishment design and process flow are appropriate. This documentary evaluation is followed by a physical inspection of the establishment for compliance with GMPs. GMPs or Good Manufacturing practices are the operational requirements necessary to enable a food business to produce safe food. A food establishment is approved or not approved for registration based on results of the inspection. Registered establishments are issued a certificate of registration with one year validity period. These establishments are routinely inspected, and the products and process water monitored to determine that they meet microbiological and chemical quality/safety criteria. The food establishment registration is subject to renewal on an annual basis based on the establishment’s performance in food safety inspection and monitoring programs. Registered establishments must comply with all legal food safety requirements. Failure to comply with national food safety regulations can results in withdrawal of an establishment’s registration; ongoing contravention of regulations is grounds for suspension/revocation of the establishment’s registration certificate.

Key Components of Food Establishment Registration

- Application Process:

- Business Details: Establishments must provide details such as the business name, address, type of food operations, and contact information.

- Required Documentation: Businesses often need to submit plans outlining the layout of the premises, and process flow.

- Inspections and Approvals:

- Initial Inspection: Before opening, BAHA’s Food Safety Department a regulatory authority will inspect the establishment to ensure it meets all health and safety requirements.

- Ongoing Inspections: Regular inspections are conducted to ensure continuous compliance with food safety standards.

- Compliance with Regulations:

- Food Safety Standards: Registered establishments must adhere to national and local food safety regulations, including proper food handling, storage, and sanitation practices.

- Employee Training: Staff must be trained in food safety practices to ensure they understand and comply with regulations.

- Documentation and Record-Keeping:

- Licensing: Establishments receive a license or certificate confirming their registration and compliance with food safety standards.

- Record Maintenance: Businesses must maintain records of their food safety practices, training, and any incidents of non-compliance or corrective actions taken.

Food Safety Application Forms

Import Certification: Ensuring Safe and Quality Food Imports for Everyone

Import certification is a critical component of food safety that ensures imported food products meet BAHA’s Food Safety standards before reaching consumers. This process involves rigorous inspections, documentation, and compliance with food safety regulations. Import conditions are determined based on import risk analysis (IRA) process which evaluates the food safety risk associated with the imported food and determines if it is acceptable for the protection of Belize’s public health. BAHA is the Regulatory Authority in Belize that issue permits for imported food.

How to Acquire Import Permits?

Routine importation of food products for which Belize’s import conditions have already been determined are regulated through issuance of import permits. Import conditions are determined based on import risk analysis (IRA) process which evaluates the food safety risk associated with the imported food and determines if it is acceptable for the protection of Belize’s public health.

Information requested in import licence applications generally includes:

a. name of the applicant;

b. importer’s name, address and contact information;

c. exporter’s name and address;

d. country of origin

e. specification of products and description;

f. quantity – expressed in the measuring units;

g. mode of transport

h. port of entry

The process for acquisition of import permits is described below.

- The application form is to be properly filled out with all relevant information and submitted at any BAHA Office, along with applicable fee. Cost per application is included in S.I. #34 of 2022.

- In some instances, additional approvals and permits/licenses from other agencies (e.g., Supplies Control Unit, Fisheries Department, Ministry of Health) are required prior to the application submission.

- Completed application forms will be submitted to the relevant authorities within BAHA for review and risk analysis, and if approved, issuance of the permit.

- If a risk analysis is required, applicant will be notified and directed to the SPS unit of BAHA. Before an import permit is issued it may also be required to conduct a risk assessment, including inspection at origin. Fees associated with a Risk Assessment is included in S.I.#34 of 2022.The result of the risk analysis determines whether:

(a) the import permit is granted, and if so, the conditions that need to be satisfied for the importation, or

(b) due to the high-risk human health, the permit is denied.

The time frame for the completion of a risk analysis may vary from several weeks to months, depending on the availability and accessibility of relevant information.

Any liability associated with the importation of any commodity is the sole responsibility of the importer.

If application is not approved, either by BAHA or other relevant Authority, applicant will be notified in a timely manner.

- Under normal circumstances, the application process for a frequently imported commodity may take up to seven (7) working days. Importers are required to submit their application(s) before shipment and to consider the processing time of these applications.

- All imports must comply with the conditions as indicated on:

- the valid import permit from BAHA

- certifications required on or conditions of importation attached to the BAHA import permit

- special permits or licenses requested by other relevant authorities.

- The issuance of an import permit does not guarantee entry as disease status of the country of origin may have changed or recalls have been implemented from the date the import permit was issued and the date the commodity arrives in Belize.

Export Certification: Ensuring Safe and High-Quality Food for International Markets

The Food Safety Services provides sanitary certification for exported food products as part of BAHA’s mission for trade facilitation. Sanitary certification is available to registered food establishment that meet requirements of the importing country. Sanitary certification is one form of assurance from the competent authority of the exporting country to the competent authority of the importing country that the certified consignment meets the food safety requirements of the importing country. These requirements are set by the importing country to ensure that imported food products meet the Appropriate Level of Protection for their citizenry.

How to Acquire Export Certification?

To acquire a Sanitary certificate the exporting establishment completes an application form and submits the completed application form along with supporting documentation for exportation to the Food Safety Services. The Turn Around Time for issuance of sanitary certificates is 1 – 3 days.

Export certificates are issued at the headquarters of the BAHA Food Safety Services in Belize City. Only registered establishments can qualify to receive sanitary certificates for exportation; however, the establishment must also be approved to export. To be approved for exportation, establishments must not only comply with national food safety regulations, but they must also meet the requirements of the importing country. Inspections of registered establishments approved for exportation include evaluation of compliance with importing country requirements. Sanitary certificates and certificates of free sale are available for consignments of food products from registered food establishments that are approved for exportation.

Key Components of Export Certification

- Regulatory Compliance:

- International Standards: Exporters must ensure their products comply with the food safety standards of the destination country, which may vary significantly from local regulations.

- Certification Requirements: Exporters must obtain the necessary certifications that often include phytosanitary certificates, health certificates, and certificates of origin.

- Inspection and Testing:

- Pre-Export Inspections: BAHA inspect food products and facilities to ensure they meet the required standards.

- Laboratory Testing: Samples are tested for contaminants, pathogens, pesticide residues, and other harmful substances to ensure safety.

- Documentation and Traceability:

- Detailed Records: Exporters must maintain detailed records of the production process, inspection results, and certifications.

- Traceability Systems: Systems are in place to trace food products back to their origin, ensuring accountability and facilitating recalls if necessary.

- Certification Issuance:

- Official Certification: Once food products pass inspections and testing, BAHA issue export certificates.

- Compliance Verification: These certificates are reviewed by the importing country’s authorities to verify compliance with their standards.

- Processing Facilities: Fish and Fishery Products are the primary food products certified for export by BAHA’s Food Safety Services. These establishments are registered; hence they are an active part of the Food Safety Services monitoring program, meeting international export requirements with the aid of food safety inspections and quality checks

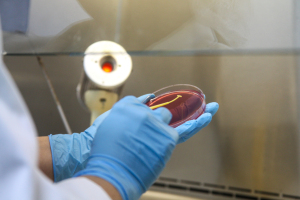

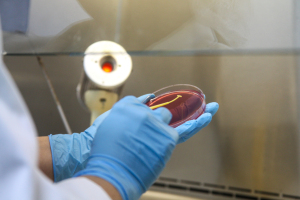

Food Microbiology Lab

Belize Agricultural Health Authority (BAHA) food microbiology lab, performs analysis of foods and feed to evaluate microbiological quality and check for the presence of foodborne pathogens. FML also provides analysis of water for total coliforms, E. Coli and Enterococci to ensure safe water for processing food. The lab also tests fungal contamination in grain, feed and agro-processed foods.

Key Functions of BAHA’s Food Microbiology Lab

- Microbiological Quality for Food:

- Examination: Performing aerobic plate count and coliform tests in food

- Detection: Testing for indicator organisms such as E. Coli

- Microbial Testing for Food:

- Pathogen Detection: Conducting test for foodborne pathogens such as Salmonella, Staphylococcus aureus, and Vibrio cholera

- Fungal Analysis: Performing yeast and mold count in agro-processed foods, feed and grain which can indicate food spoilage

- Water Quality:

- Monitoring: Testing water from food processing facilities to ensure it meets safety standards

- Regulatory Compliance:

- Standards Adherence: Ensuring that food products comply with national and international food safety standards and regulations.

- Certification: Providing certification for food products that meet safety standards

- Research and Development:

- New Methods: Developing and validating new testing methods and technologies for more accurate and efficient detection of microorganisms.

- Outbreak Investigation:

- Support Source Tracing: Providing results of microbiological testing of food linked to possible foodborne illness outbreaks

Chemical Analysis Lab

Belize Agricultural Health Authority (BAHA) chemical analysis lab Laboratory is equipped with a wide range of analytical instrumentation including Gas Chromatography, Liquid Chromatography, Mass Spectrometry and Inductively Coupled Plasma Optical Emission Spectrophotometry for analysing chemical residues and contaminants in food and animal feed. CAL also provides water quality testing as a part of the Food Safety Monitoring programs and for private clients. In addition, the lab offers compositional testing in food and agricultural products based on the needs of those industries

Key Functions of BAHA’s Chemical Analysis Lab

- Chemical Residue Analysis:

- Pesticide Residues: Testing for pesticide residues in fruits and vegetables to ensure they are within Maximum Residue Limits (MRLs).

- Veterinary Drug Residues: Testing for drug residues in meats, poultry and milk to ensure they are within Maximum Residue Limits (MRLs).

- Additives and Preservatives: Identifying and quantifying food additives to ensure they are used within permissible limits.

- Food Contaminant Analysis:

- Mycotoxins: Testing for mycotoxins such as aflatoxins to ensure compliance with safety standards

- Heavy Metals:

- Food Compositional Analysis:

- Content: Verifying the levels of components in food based on the needs of the industry

- Water Quality:

- Monitoring: Testing of water from food processing facilities to ensure minimum water quality

- Research and Development:

- New Methods: Developing and validating new testing methods and technologies for more accurate and efficient analysis of chemical components

- Regulatory Compliance:

- Standards Adherence: Ensuring that food products comply with national and international safety standards and regulations.

HACCP Recognition: Ensuring Safe Food for Everyone

HACCP (Hazard Analysis and Critical Control Points) is a crucial aspect of the modern food safety management system. The HACCP system is process and product specific, it is based on identification of food safety hazards and establishment of specific points in the process chain to control/diminish levels of these hazards (Critical Control Points). Food safety hazards can be biological, physical or chemical in nature.

BAHA registered food processing enterprises which implement a HACCP system are audited on an annual basis by designated BAHA auditors. The Food Safety Services of BAHA is legally authorized to carry out HACCP audits of food processing facilities including fishing vessels as per the Belize Agricultural Health Authority (Food Safety) regulations, S.I. No. 25 of 2001. BAHA registered food establishments seeking official recognition of their HACCP system must provide documentation of their HACCP system (HACCP plan, GMP and SSCP Programs). On acceptance of the documentation, the audit process is initiated.

What is HACCP Recognition?

HACCP recognition is the formal acknowledgment by the Food Safety Services of BAHA that a food processing facility has implemented and maintains an effective HACCP system.

Benefits to the General Public

- Ensuring Food Safety:

- Preventing Contamination: HACCP systems help prevent foodborne illnesses by controlling hazards throughout the food production process.

- High Standards: Businesses recognized for HACCP compliance adhere to high food safety standards, ensuring the food you consume is safe.

- Building Consumer Confidence:

- Trust in Food Products: Knowing that a food business follows HACCP principles increases consumer trust in the safety and quality of their products.

- Transparency: HACCP recognition provides transparency, allowing consumers to make informed choices about the food they buy.

- Supporting Public Health:

- Reducing Illnesses: Effective HACCP systems reduce the risk of foodborne illnesses, contributing to overall public health.

- Safe Food Supply: Ensuring a safe food supply benefits everyone, from consumers to food producers and distributors.

- Promoting Industry Best Practices:

- Encouraging Compliance: HACCP recognition encourages food businesses to adopt and maintain best practices in food safety.

- Continuous Improvement: The HACCP system fosters a culture of continuous improvement, enhancing food safety standards over time.

- Advantage:

- Registered food processing facilities that are HACCP recognized/certified, can export their products to specific international markets.

About BAHA’s Food Safety Department

Trade Facilitation

Food Inspection

BAHA’s Food Safety Laboratories

How can the Food Safety Department help you?

Use the contact form below to contact us or check our FAQ to help assist you in your queries.

Foodborne illness, also known as food poisoning, is an infection or intoxication caused by consuming contaminated food or beverages. Common symptoms include nausea, vomiting, diarrhea, abdominal pain, and fever. It can be caused by bacteria, viruses, parasites, or chemical contaminants.

If you suspect food poisoning:

Seek Medical Attention: Contact a healthcare provider, especially if symptoms are severe.

Report It: Inform BAHA about the suspected foodborne illness.

Stay Hydrated: Drink plenty of fluids to prevent dehydration, especially if you are experiencing diarrhea or vomiting.

Contaminated food may not always show visible signs. However, some indicators include:

Off Smell: A foul or unusual odor.

Color Changes: Discoloration or unusual colors.

Texture Changes: Slimy or sticky texture.

Visible Mold: Presence of mold or unusual growths.

Safe cooking temperatures for common foods are:

Poultry (chicken, turkey): 165°F (74°C)

Ground meats (beef, pork, lamb): 160°F (71°C)

Beef, pork, lamb (steaks, chops, roasts): 145°F (63°C) with a 3-minute rest time

Fish and seafood: 145°F (63°C)

Eggs: Cook until both the yolk and white are firm.

Expiration dates help ensure the safety and quality of food products. Consuming food past its expiration date can increase the risk of foodborne illness due to the potential growth of harmful bacteria or spoilage. Always check and adhere to expiration dates for optimal safety.

Overview

Food Safety Department

The Belize Agricultural Health Authority is the competent authority for Food Safety in Belize. In this capacity, the Food Safety Services, one of the four technical departments of BAHA oversees, along with relevant partners and stakeholders, the National Food Control System of Belize thereby ensuring, as best as possible, that the food available for consumption and produced within the country is safe and wholesome. The Food Safety Services has responsibility and authority for monitoring, inspecting, approving and controlling food safety systems of food processing establishments, and for regulation of export and import certification for food commodities. These responsibilities are supported in law by the BAHA Act, Ch. 211 of the Substantive regulations of Belize, and other enabling regulations including the Belize Agricultural Health Authority (Food Safety) regulations, S.I. No. 25 of 2001.

What We Do/Who We Are

Food Safety Priorities

Import permits regulate the importation of food products into Belize

Food safety export certificates are issued for food products from registered establishments approved for exportation.

Food safety registration is mandatory for exporting food enterprises registered with BAHA’s Food Safety Services.

BAHA Food Safety inspectors oversee meat inspection at registered slaughterhouses in the country. The inspection program has two main goals: ensuring that only healthy animals are slaughtered for human consumption and that these animals are free from zoonotic and other diseases.

Food safety inspections ensure that food producers adhere to Good Manufacturing Practices (GMP), which are mandated operational standards for producing safe food. These practices are outlined in the BAHA (Food Safety) Regulations. Inspections verify compliance with these standards, safeguarding the production of safe food for consumers.

Food safety microbiological testing is conducted at the Central Investigation Laboratory in Belize City, analyzing foods, feed, and water for foodborne pathogens and indicator bacteria. Tests available include screening for pathogens such as Salmonella spp., Staphylococcus aureus, Vibrio cholerae, as well as Aerobic Mesophilic bacteria, coliform bacteria, and Escherichia coli (E. coli). These tests help ensure the safety of food products by identifying harmful microorganisms that could pose health risks to consumers.

Food Safety services oversee sanitary audits of HACCP programs on Belize-flagged High Seas Fishing Vessels (BHSFU), registered by IMMARBE and licensed by BHSFU. These audits, crucial for international market access like the EU, ensure the safety of fishery products. Authorized vessels can export to the EU under specific regulations, with BAHA recognized as the Competent Authority. This ensures health controls and final conditions for fishery products exported from Belize, maintaining compliance with EU standards.

The Chemical Analysis Laboratory at the Food Safety headquarters in Belize City conducts comprehensive testing for chemical residues and contaminants in foods, feeds, and agricultural samples.

HACCP (Hazard Analysis and Critical Control Point) is a food safety system aimed at preventing hazards in food production. BAHA audits registered food processing enterprises annually to ensure HACCP compliance.

Food Safety Inspection

Ensuring Food Safety Through Inspections of Food Establishments

BAHA’s Food Safety Services inspectorate conducts routine inspections of registered food processing establishments including slaughterhouses, fish & fishery processing facilities, dairy and agro-processing facilities. Inspections verify compliance of the food producer with Good Manufacturing Practices (GMP) which are the legislated operational requirements necessary to enable a food business to produce safe food (Second Schedule “General Principles of Food Hygiene” of the BAHA (Food Safety) Regulations (S.I. No. 25 of 2001).

What Is Food Safety Inspections?

Food safety inspections are systematic assessments conducted by the Food Safety Services of the Belize Agricultural Health Authority to ensure that food processing establishments comply with established food safety standards. BAHA’s food safety inspectors evaluate various aspects of food production, including hygiene and sanitation practices, processing methods, facility layout, process flow, and storage conditions

Importance of Food Safety Inspections

- Protecting Public Health: All animals destined for slaughter are screened for abnormalities which can indicate poor health, sickness or clinical disease, and foods that are unfit for human consumption are condemned and destroyed.

- Ensuring Product Safety: Food Safety inspections verify compliance of the food producer with Good Hygiene Practices and Good Manufacturing Practices (GMP) which minimize the risk of food contamination

- Building Consumer Confidence: Regular inspections of registered facilities ensure that consumers can trust the safety and integrity of the food supply chain.

Key Areas of Food Safety Inspections

Ensuring that processing conditions and procedures follow Good Hygiene Practices and Good Manufacturing Practices (GMP) to prevent contamination and maintain food quality. Some key aspects of GHP and GMP include:

- Building and equipment design: Layout and design should prevent contamination of product. This includes the structure of and materials of which walls, ceilings, food contact surfaces are constructed, location and design of sanitary facilities, entrances and exits and flow of production process …………………

- Storage Facilities: there must be adequate segregation, chill storage for materials that require refrigeration, and distribution……….

- Process Equipment/Machinery: must be of proper …. To allow proper cleaning and disinfection and must be non-toxic. Constructed and maintained to preclude contamination

- Personnel Standards: attire must be clean, PPE headgear to cover hair, handwashing practices; jewelry, cosmetics

- Food Handling Practices:

- Quality Assurance: Product and Production processes, Processing ?Conditions? including environmental conditions should be monitored and controlled including temperatures, cleaning?

- Pest Prevention: Iwritten t is critical to avoid contamination of ingredients/incoming materials, products and food contact materials/surfaces by pests. Pathogens /sources of Human disease

- Cleaning System: water, chemicals, written

- Management Control: policies and resources

Food Establishment Registration

Food Establishment Registration: Ensuring Safe and Quality Food for Everyone

Food establishment registration involves the official recording of a food establishment with BAHA’s Food Safety Services. Food Export Enterprises are legally required to register with BAHA. Registration ensures that these establishments meet specific safety and hygiene standards. Registered establishments fall under the Food Safety Services’ inspection and monitoring program; they are routinely inspected for compliance with Good Manufacturing Practices and other national Food Safety requirements, and their products are regularly sampled and tested.

For first time registration of a food establishment a completed registration form with information on the food establishment including legal name, legal status, location, size, scope of production, production volumes, description of the production process, facility layout and design and other information of relevance is submitted. A preliminary evaluation is conducted based on the documents provided to ensure the establishment design and process flow are appropriate. This documentary evaluation is followed by a physical inspection of the establishment for compliance with GMPs. GMPs or Good Manufacturing practices are the operational requirements necessary to enable a food business to produce safe food. A food establishment is approved or not approved for registration based on results of the inspection.

Registered establishments are issued a certificate of registration with one year validity period. These establishments are routinely inspected, and the products and process water monitored to determine that they meet microbiological and chemical quality/safety criteria. The food establishment registration is subject to renewal on an annual basis based on the establishment’s performance in food safety inspection and monitoring programs. Registered establishments must comply with all legal food safety requirements. Failure to comply with national food safety regulations can results in withdrawal of an establishment’s registration; ongoing contravention of regulations is grounds for suspension/revocation of the establishment’s registration certificate.

What is the Process of Registering your Food Establishment?

For first time registration of a food establishment, a completed registration form with information on the food establishment including legal name, legal status, location, size, scope of production, production volumes, description of the production process, facility layout and design and other information of relevance is submitted. A preliminary evaluation is conducted based on the documents provided to ensure the establishment design and process flow are appropriate. This documentary evaluation is followed by a physical inspection of the establishment for compliance with GMPs. GMPs or Good Manufacturing practices are the operational requirements necessary to enable a food business to produce safe food. A food establishment is approved or not approved for registration based on results of the inspection. Registered establishments are issued a certificate of registration with one year validity period. These establishments are routinely inspected, and the products and process water monitored to determine that they meet microbiological and chemical quality/safety criteria. The food establishment registration is subject to renewal on an annual basis based on the establishment’s performance in food safety inspection and monitoring programs. Registered establishments must comply with all legal food safety requirements. Failure to comply with national food safety regulations can results in withdrawal of an establishment’s registration; ongoing contravention of regulations is grounds for suspension/revocation of the establishment’s registration certificate.

Key Components of Food Establishment Registration

- Application Process:

- Business Details: Establishments must provide details such as the business name, address, type of food operations, and contact information.

- Required Documentation: Businesses often need to submit plans outlining the layout of the premises, and process flow.

- Inspections and Approvals:

- Initial Inspection: Before opening, BAHA’s Food Safety Department a regulatory authority will inspect the establishment to ensure it meets all health and safety requirements.

- Ongoing Inspections: Regular inspections are conducted to ensure continuous compliance with food safety standards.

- Compliance with Regulations:

- Food Safety Standards: Registered establishments must adhere to national and local food safety regulations, including proper food handling, storage, and sanitation practices.

- Employee Training: Staff must be trained in food safety practices to ensure they understand and comply with regulations.

- Documentation and Record-Keeping:

- Licensing: Establishments receive a license or certificate confirming their registration and compliance with food safety standards.

- Record Maintenance: Businesses must maintain records of their food safety practices, training, and any incidents of non-compliance or corrective actions taken.

Application Forms

Food Safety Health Application Forms

Import Certification

Import Certification: Ensuring Safe and Quality Food Imports for Everyone

Import certification is a critical component of food safety that ensures imported food products meet BAHA’s Food Safety standards before reaching consumers. This process involves rigorous inspections, documentation, and compliance with food safety regulations. Import conditions are determined based on import risk analysis (IRA) process which evaluates the food safety risk associated with the imported food and determines if it is acceptable for the protection of Belize’s public health. BAHA is the Regulatory Authority in Belize that issue permits for imported food.

How to Acquire Import Permits?

Routine importation of food products for which Belize’s import conditions have already been determined are regulated through issuance of import permits. Import conditions are determined based on import risk analysis (IRA) process which evaluates the food safety risk associated with the imported food and determines if it is acceptable for the protection of Belize’s public health.

Information requested in import licence applications generally includes:

a. name of the applicant;

b. importer’s name, address and contact information;

c. exporter’s name and address;

d. country of origin

e. specification of products and description;

f. quantity – expressed in the measuring units;

g. mode of transport

h. port of entry

The process for acquisition of import permits is described below.

- The application form is to be properly filled out with all relevant information and submitted at any BAHA Office, along with applicable fee. Cost per application is included in S.I. #34 of 2022.

- In some instances, additional approvals and permits/licenses from other agencies (e.g., Supplies Control Unit, Fisheries Department, Ministry of Health) are required prior to the application submission.

- Completed application forms will be submitted to the relevant authorities within BAHA for review and risk analysis, and if approved, issuance of the permit.

- If a risk analysis is required, applicant will be notified and directed to the SPS unit of BAHA. Before an import permit is issued it may also be required to conduct a risk assessment, including inspection at origin. Fees associated with a Risk Assessment is included in S.I.#34 of 2022.The result of the risk analysis determines whether:

(a) the import permit is granted, and if so, the conditions that need to be satisfied for the importation, or

(b) due to the high-risk human health, the permit is denied.

The time frame for the completion of a risk analysis may vary from several weeks to months, depending on the availability and accessibility of relevant information.

Any liability associated with the importation of any commodity is the sole responsibility of the importer.

If application is not approved, either by BAHA or other relevant Authority, applicant will be notified in a timely manner.

Export Certification

Export Certification: Ensuring Safe and High-Quality Food for International Markets

The Food Safety Services provides sanitary certification for exported food products as part of BAHA’s mission for trade facilitation. Sanitary certification is available to registered food establishment that meet requirements of the importing country. Sanitary certification is one form of assurance from the competent authority of the exporting country to the competent authority of the importing country that the certified consignment meets the food safety requirements of the importing country. These requirements are set by the importing country to ensure that imported food products meet the Appropriate Level of Protection for their citizenry.

How to Acquire Export Certification?

To acquire a Sanitary certificate the exporting establishment completes an application form and submits the completed application form along with supporting documentation for exportation to the Food Safety Services. The Turn Around Time for issuance of sanitary certificates is 1 – 3 days.

Export certificates are issued at the headquarters of the BAHA Food Safety Services in Belize City. Only registered establishments can qualify to receive sanitary certificates for exportation; however, the establishment must also be approved to export. To be approved for exportation, establishments must not only comply with national food safety regulations, but they must also meet the requirements of the importing country. Inspections of registered establishments approved for exportation include evaluation of compliance with importing country requirements. Sanitary certificates and certificates of free sale are available for consignments of food products from registered food establishments that are approved for exportation.

Key Components of Export Certification

- Regulatory Compliance:

- International Standards: Exporters must ensure their products comply with the food safety standards of the destination country, which may vary significantly from local regulations.

- Certification Requirements: Exporters must obtain the necessary certifications that often include phytosanitary certificates, health certificates, and certificates of origin.

- Inspection and Testing:

- Pre-Export Inspections: BAHA inspect food products and facilities to ensure they meet the required standards.

- Laboratory Testing: Samples are tested for contaminants, pathogens, pesticide residues, and other harmful substances to ensure safety.

- Documentation and Traceability:

- Detailed Records: Exporters must maintain detailed records of the production process, inspection results, and certifications.

- Traceability Systems: Systems are in place to trace food products back to their origin, ensuring accountability and facilitating recalls if necessary.

- Certification Issuance:

- Official Certification: Once food products pass inspections and testing, BAHA issue export certificates.

- Compliance Verification: These certificates are reviewed by the importing country’s authorities to verify compliance with their standards.

- Processing Facilities: Fish and Fishery Products are the primary food products certified for export by BAHA’s Food Safety Services. These establishments are registered; hence they are an active part of the Food Safety Services monitoring program, meeting international export requirements with the aid of food safety inspections and quality checks

Laboratory Services

Food Microbiology Lab

Belize Agricultural Health Authority (BAHA) food microbiology lab, performs analysis of foods and feed to evaluate microbiological quality and check for the presence of foodborne pathogens. FML also provides analysis of water for total coliforms, E. Coli and Enterococci to ensure safe water for processing food. The lab also tests fungal contamination in grain, feed and agro-processed foods.

Key Functions of BAHA’s Food Microbiology Lab

- Microbiological Quality for Food:

- Examination: Performing aerobic plate count and coliform tests in food

- Detection: Testing for indicator organisms such as E. Coli

- Microbial Testing for Food:

- Pathogen Detection: Conducting test for foodborne pathogens such as Salmonella, Staphylococcus aureus, and Vibrio cholera

- Fungal Analysis: Performing yeast and mold count in agro-processed foods, feed and grain which can indicate food spoilage

- Water Quality:

- Monitoring: Testing water from food processing facilities to ensure it meets safety standards

- Regulatory Compliance:

- Standards Adherence: Ensuring that food products comply with national and international food safety standards and regulations.

- Certification: Providing certification for food products that meet safety standards

- Research and Development:

- New Methods: Developing and validating new testing methods and technologies for more accurate and efficient detection of microorganisms.

- Outbreak Investigation:

- Support Source Tracing: Providing results of microbiological testing of food linked to possible foodborne illness outbreaks

Chemical Analysis Lab

Belize Agricultural Health Authority (BAHA) chemical analysis lab Laboratory is equipped with a wide range of analytical instrumentation including Gas Chromatography, Liquid Chromatography, Mass Spectrometry and Inductively Coupled Plasma Optical Emission Spectrophotometry for analysing chemical residues and contaminants in food and animal feed. CAL also provides water quality testing as a part of the Food Safety Monitoring programs and for private clients. In addition, the lab offers compositional testing in food and agricultural products based on the needs of those industries

Key Functions of BAHA’s Chemical Analysis Lab

- Chemical Residue Analysis:

- Pesticide Residues: Testing for pesticide residues in fruits and vegetables to ensure they are within Maximum Residue Limits (MRLs).

- Veterinary Drug Residues: Testing for drug residues in meats, poultry and milk to ensure they are within Maximum Residue Limits (MRLs).

- Additives and Preservatives: Identifying and quantifying food additives to ensure they are used within permissible limits.

- Food Contaminant Analysis:

- Mycotoxins: Testing for mycotoxins such as aflatoxins to ensure compliance with safety standards

- Heavy Metals:

- Food Compositional Analysis:

- Content: Verifying the levels of components in food based on the needs of the industry

- Water Quality:

- Monitoring: Testing of water from food processing facilities to ensure minimum water quality

- Research and Development:

- New Methods: Developing and validating new testing methods and technologies for more accurate and efficient analysis of chemical components

- Regulatory Compliance:

- Standards Adherence: Ensuring that food products comply with national and international safety standards and regulations.

HACCP Recognition

HACCP Recognition: Ensuring Safe Food for Everyone

HACCP (Hazard Analysis and Critical Control Points) is a crucial aspect of the modern food safety management system. The HACCP system is process and product specific, it is based on identification of food safety hazards and establishment of specific points in the process chain to control/diminish levels of these hazards (Critical Control Points). Food safety hazards can be biological, physical or chemical in nature.

BAHA registered food processing enterprises which implement a HACCP system are audited on an annual basis by designated BAHA auditors. The Food Safety Services of BAHA is legally authorized to carry out HACCP audits of food processing facilities including fishing vessels as per the Belize Agricultural Health Authority (Food Safety) regulations, S.I. No. 25 of 2001. BAHA registered food establishments seeking official recognition of their HACCP system must provide documentation of their HACCP system (HACCP plan, GMP and SSCP Programs). On acceptance of the documentation, the audit process is initiated.

What is HACCP Recognition?

HACCP recognition is the formal acknowledgment by the Food Safety Services of BAHA that a food processing facility has implemented and maintains an effective HACCP system.

Benefits to the General Public

- Ensuring Food Safety:

- Preventing Contamination: HACCP systems help prevent foodborne illnesses by controlling hazards throughout the food production process.

- High Standards: Businesses recognized for HACCP compliance adhere to high food safety standards, ensuring the food you consume is safe.

- Building Consumer Confidence:

- Trust in Food Products: Knowing that a food business follows HACCP principles increases consumer trust in the safety and quality of their products.

- Transparency: HACCP recognition provides transparency, allowing consumers to make informed choices about the food they buy.

- Supporting Public Health:

- Reducing Illnesses: Effective HACCP systems reduce the risk of foodborne illnesses, contributing to overall public health.

- Safe Food Supply: Ensuring a safe food supply benefits everyone, from consumers to food producers and distributors.

- Promoting Industry Best Practices:

- Encouraging Compliance: HACCP recognition encourages food businesses to adopt and maintain best practices in food safety.

- Continuous Improvement: The HACCP system fosters a culture of continuous improvement, enhancing food safety standards over time.

- Advantage:

- Registered food processing facilities that are HACCP recognized/certified, can export their products to specific international markets.

Publications

About BAHA’s Food Safety Department

Trade Facilitation

Food Inspection

BAHA’s Food Safety Laboratories

Contact Us

How can the Food Safety Department help you?

Foodborne illness, also known as food poisoning, is an infection or intoxication caused by consuming contaminated food or beverages. Common symptoms include nausea, vomiting, diarrhea, abdominal pain, and fever. It can be caused by bacteria, viruses, parasites, or chemical contaminants.

If you suspect food poisoning:

Seek Medical Attention: Contact a healthcare provider, especially if symptoms are severe.

Report It: Inform BAHA about the suspected foodborne illness.

Stay Hydrated: Drink plenty of fluids to prevent dehydration, especially if you are experiencing diarrhea or vomiting.

Contaminated food may not always show visible signs. However, some indicators include:

Off Smell: A foul or unusual odor.

Color Changes: Discoloration or unusual colors.

Texture Changes: Slimy or sticky texture.

Visible Mold: Presence of mold or unusual growths.

Safe cooking temperatures for common foods are:

Poultry (chicken, turkey): 165°F (74°C)

Ground meats (beef, pork, lamb): 160°F (71°C)

Beef, pork, lamb (steaks, chops, roasts): 145°F (63°C) with a 3-minute rest time

Fish and seafood: 145°F (63°C)

Eggs: Cook until both the yolk and white are firm.

Expiration dates help ensure the safety and quality of food products. Consuming food past its expiration date can increase the risk of foodborne illness due to the potential growth of harmful bacteria or spoilage. Always check and adhere to expiration dates for optimal safety.